It is often said that anything relating to Texas is big, but be aware that the neighboring state of Oklahoma has something that even Texans would probably have to admit is grand, even by Texas standards. I’m referring to the National Cowboy and Western Heritage Museum, located in Oklahoma City, Oklahoma.

The first thing you will notice upon arriving at the Museum are the exquisitely designed buildings which house the exhibits and collections.

No matter which way you look, you will see beautiful buildings and extremely well landscaped and manicured grounds. The buildings are modern and airy, and contain well over 200,000 square feet of exhibition, office and auditorium space.

It soon becomes apparent that the Museum collection contains many exhibits of truly grand stature, as you can see from the wing in the photograph above, which contains only one item, a massive sculpture called “The End of the Trail,” a well known piece of art created by James Earle Fraser for the 1915 Pan-Pacific Exhibition held in San Francisco, California.

The photograph above, taken from inside the building, gives a good indication of the size of this sculpture. The children do not come close to reaching even the top of the pedestal on which the sculpture stands.

The grounds of the National Cowboy Museum are gorgeous, with man-made streams, waterfalls, and Koi ponds artfully placed throughout the beautifully landscaped gardens.Â

As you stroll through the gardens, you will see many varied sculptures, such as this piece depicting a mare and her foal.

When you reach the spot where this giant (I mean HUGE) sculpture of Wild Bill Hickock Buffalo Bill Cody is located, you start to realize that many of the exhibits at the Museum were created without constraints on size. I don’t know whether the buildings were designed to be large in order to house the massive exhibits, or whether the exhibits were selected to fill the massive buildings. Whatever the case, it all seems to work together well.

Inside the Museum are many different wings, each housing a varied collection of themed exhibits, such as this diorama of buffalo hunters contained in the Joe Grandee Museum of the Frontier West.

The U.S. Army Cavalry is well represented in the displays, and again, the exhibits are massive and full scale.

Even the American Rodeo Gallery contains many life sized sculptures and displays, such as this bronc rider seen in the photograph above.Â

This finely detailed coat is just one of the hundreds of pieces of cowboy and western apparel on display at the museum. Each piece on display is of similarly high quality as the coat seen here.

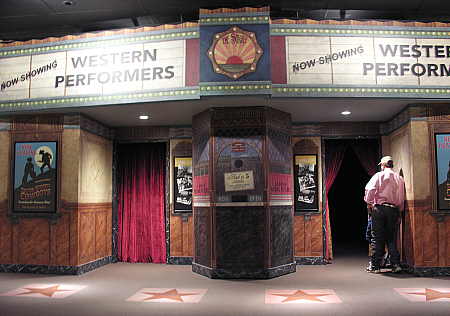

Because westerns, or “oaters” were such a large part of the American culture for those of us who pre-date Generation X’ers, the Museum contains a separate Western Performers Gallery. Within this gallery is the theater shown above, where you can enter and watch an old western while you rest up for more exploration of the Museum’s many exhibits.

In addition to the galleries pictured in this post, the Museum has a number of galleries which house a large and valuable collection of fine art relating to cowboys and western heritage. Because of copyright concerns, the Museum (understandably) forbids photography in these galleries, so I have no photographs to include here. Rest assured, however, that the quality of the art on display is on a par with the quality of the other exhibits that I have included in this post.

Also there are galleries and wings that are not conducive to casual photography, due to lighting and display considerations. For instance, the Weitzenhoffer Gallery of Fine Arms contains a collection of artistic, historic and rare firearms, housed in glass display cases which cast reflections making photography challenging, at best. So too for the Native American Gallery.  There is also a wing of the Museum called Prosperity Junction, which is an indoor re-creation of a typical frontier town. It is well worth seeing, however the dim lighting makes casual photography difficult or impossible. Additionally, the Museum includes the Children’s Cowboy Corral, where the little ones can wear western clothing, build a fire and fix some “grub” at the chuck wagon for their parents. It is a hands-on environment, and the kids can touch to their hearts content.

All in all, the National Cowboy and Western Heritage Museum is a wonderful place to visit when traveling to or through Oklahoma City. Be sure to allocate enough time to see the Museum in it’s entirety, which could easily take several hours if you like to study all of the displays and enjoy all of the artwork.

Well done, Oklahomans. This museum is a great asset to your state, and a real treasure for all of us.