I have a goal of visiting every major attraction along (or close to) the famous Route 66 within my lifetime. Why this is, I couldn’t tell you. Never-the-less, I plug away at it. So here is yet another Route 66 attraction that is well worth taking the time to see if you happen to be traveling along Interstate 40 in northern Arizona. I’m referring to the Petrified Forest National Park located within the beautiful Painted Desert of Arizona.

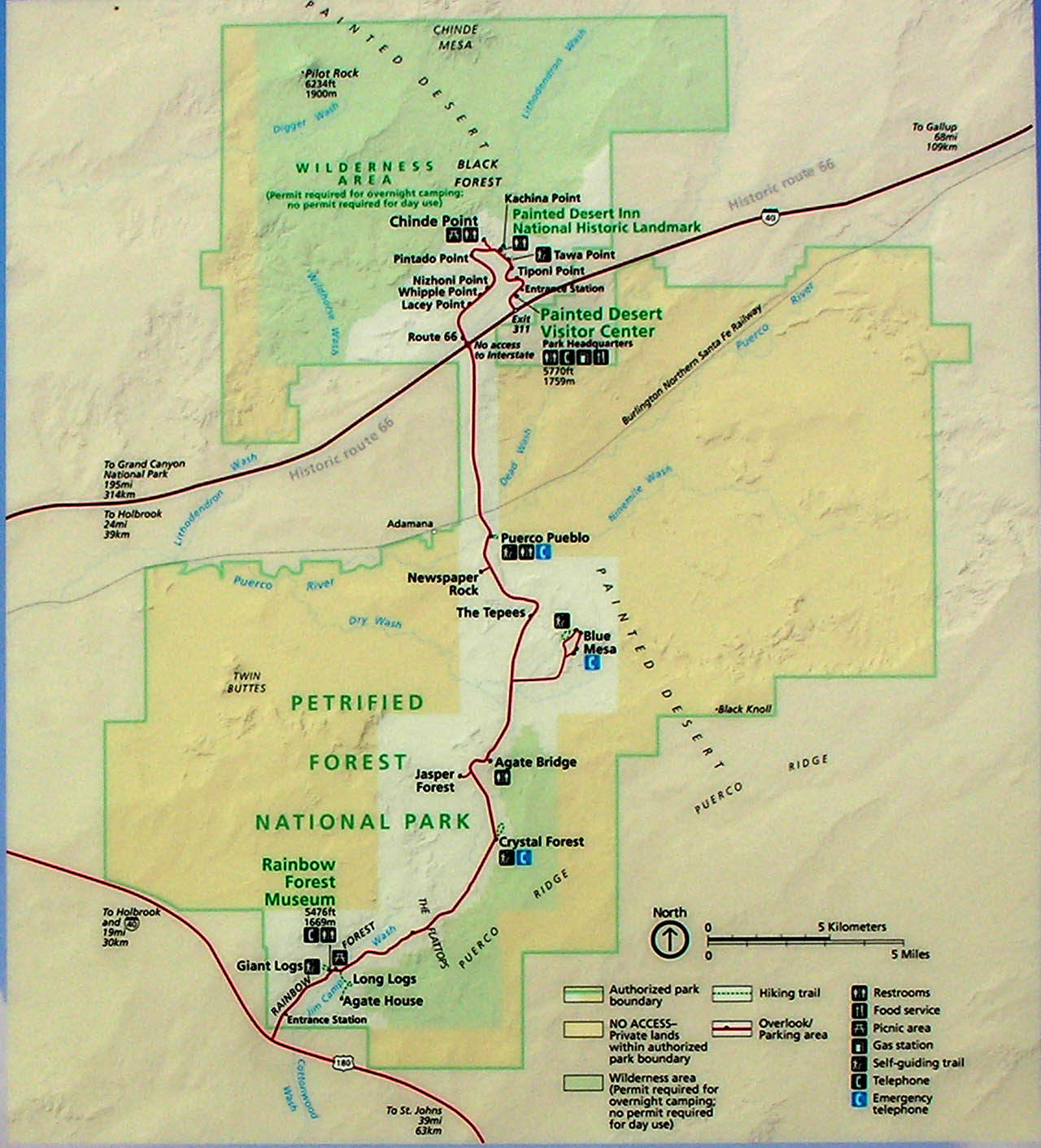

This map shows the outline of the park, along with the major features contained therein. You may notice that visiting the park, and driving along the main park road will not add a major amount of time to your east or west-bound travel along the interstate. There is a lot to see within the park, however, so you may want to allocate sufficient time for hiking and sightseeing during your visit. If you are west-bound on the Interstate, the first thing you will encounter as you divert off the main road is the visitors center, where you can obtain information about the park. The visitors center is exactly what you might expect, so I have not included any photos of it in this post.

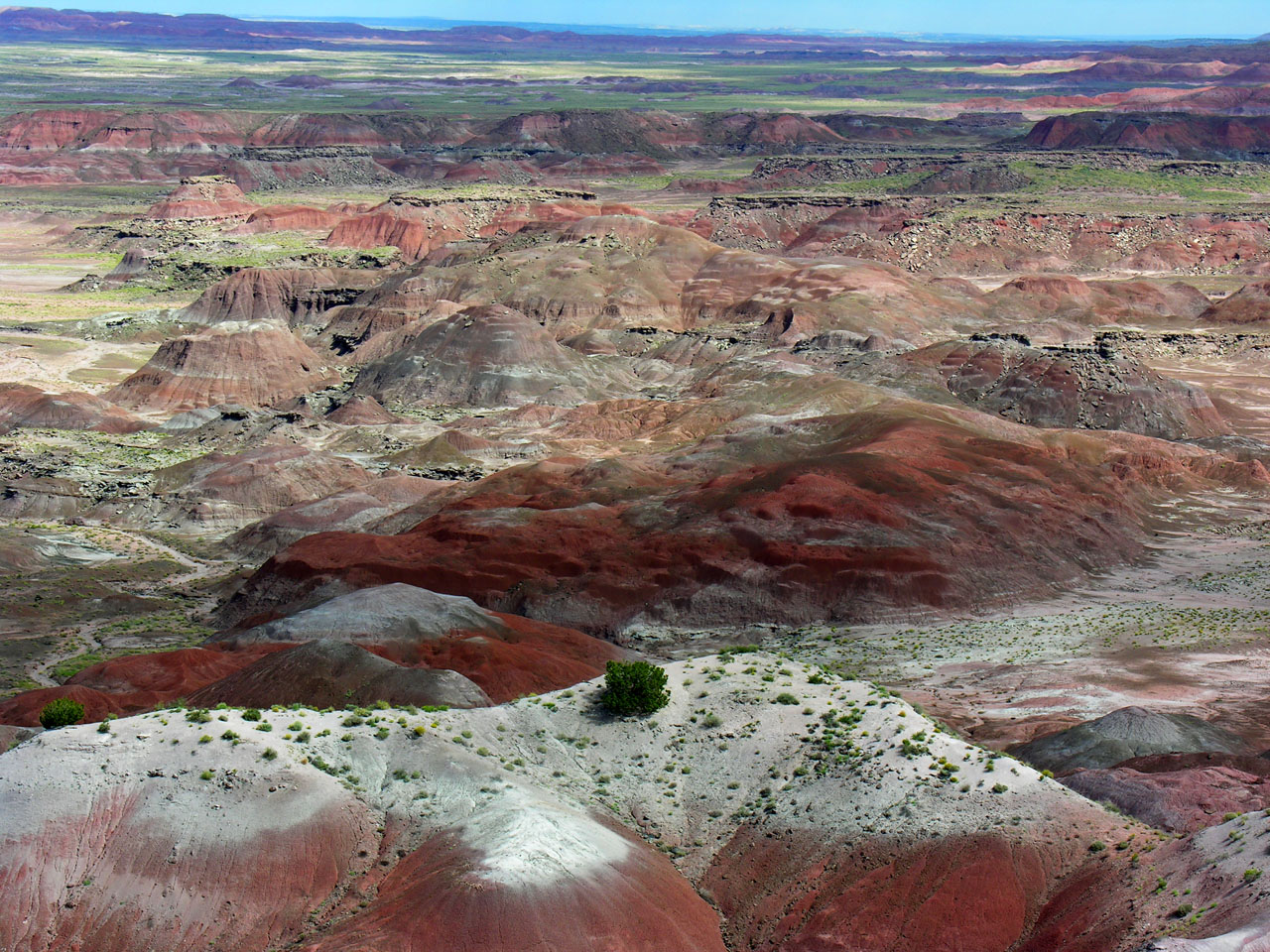

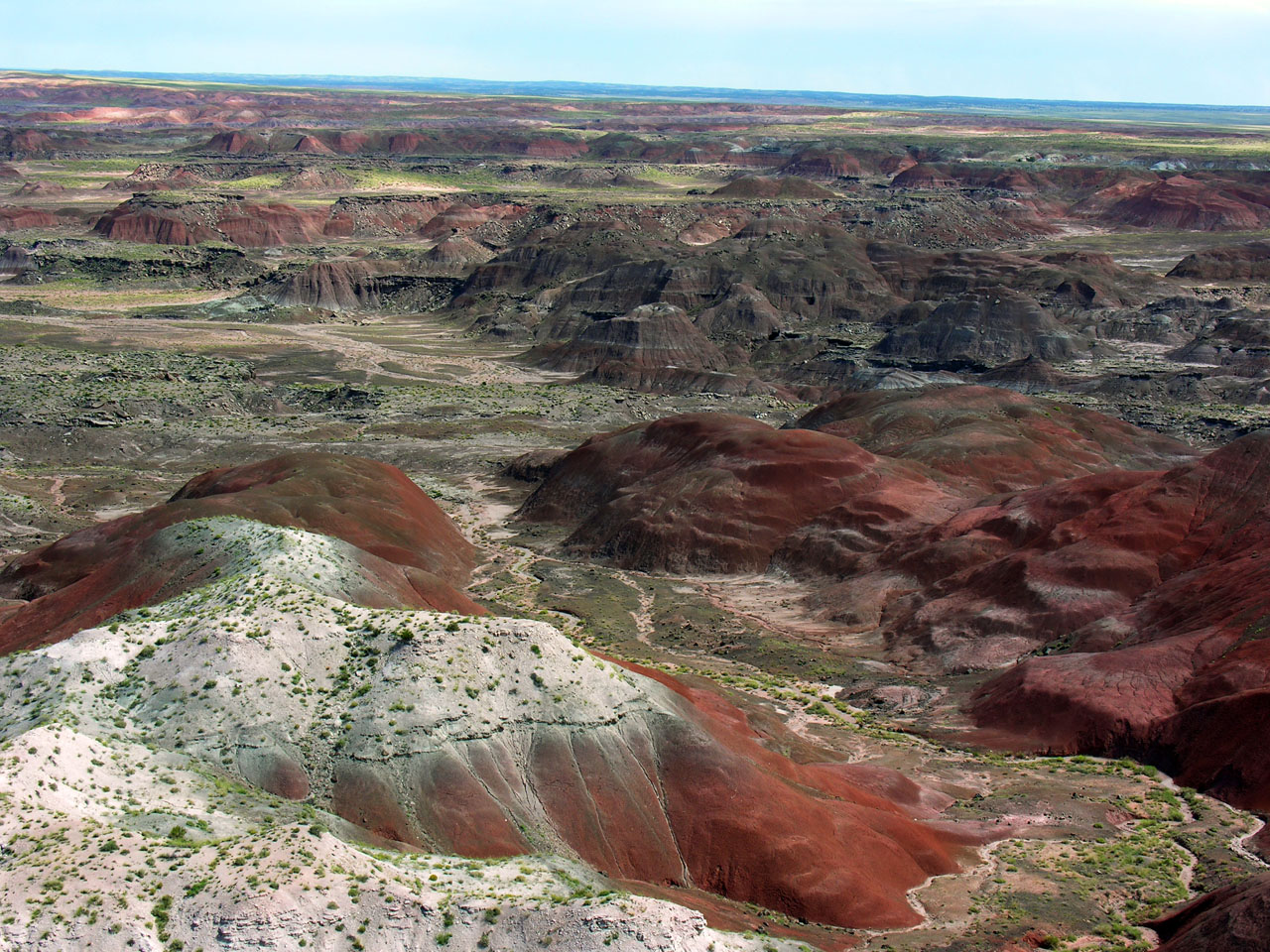

After paying the entrance fee at the park entry kiosk, the first thing you encounter along the park road are overlooks from which you have excellent vantage points of the spectacular Painted Desert.

If you happen along this route at the right time of the year, wildflowers abound, adding a colorful touch to the already beautiful scenery.

As you continue driving, you are rewarded with views of the desert in all directions, each view seeming more spectacular than the previous one.

The clean desert air, combined with the elevated vantage point afforded by the turnouts allow you to see the hills and valleys for what seems a hundred miles.

There are hiking trails along the way that will allow you to explore the area much more thoroughly than if you simply stayed in your automobile.

Soon you will arrive at the Painted Desert Inn National Historical Landmark, which is well worth exploring.

Across the road from the Inn are additional service buildings, built in the same Pueblo style as the Painted Desert Inn.

Visitors are welcome to enter the Inn, where you can see the wonderful architecture and decorating that make this such a special place.

It is worth the effort to search for the little details that make this place unique, such as this hand-crafted light fixture in the bar area.

This mural depicts the dance and ceremonial costumes of the Native Americans from the region. You will find similar artwork throughout the Painted Desert Inn.

Back on the road heading south, you find yourself within an area of badlands.  Take the time to enjoy the scenery, as these types of geological formations occur only in a few areas of the United States

The starkness of the landscape contrasts nicely with the beauty and colors of the barren, rocky hills. I can only imaging what this entire area must look like in the evening alpenglow. Even in the flat, monochromatic lighting of the mid-day sun, the colors pop out at you, daring you to take photograph after photograph.

The jagged landscape appears as if someone had picked it up and crumpled it in their hands. Can you imagine early travelers attempting to traverse this region?

The perceptive tourist will notice the varied and unusual rock formations that seem to occur whichever way one looks. Combined with the wildflowers, they make excellent photographic subjects.

Besides the isolated rock outcroppings, there are many examples of cacti and desert vegetation managing to eke out an existence in the hot, arid desert climate.

This area of badlands has a nice paved pathway that makes for pretty easy hiking. It is a great way to stretch your legs from all the driving you might have been doing along Interstate 40, and allows you to see the details that make up this terrain from close-up.

The colors in these badlands seem to change minute-by-minute, particularly when the clouds dance along in the sky above.

The trail through the badland canyons is paved, as you can see here. This is the only section of the trail the really causes physical exertion, so take it slow and easy here. The rest of the trail is relatively flat, making it easy to hike. I witnessed tourists of all ages and conditioning walking along the trail, so don’t be hesitant to give it a try.

One thing you notice as you walk the badlands trail is that the scenery looks entirely different from the bottom looking up, as opposed to looking down on the badlands from above.

As you can see, I wasn’t pulling your leg when I stated that the badlands trail flattens out at the bottom. The views along this section of trail are great, and you can enjoy a leisurely stroll as you partake of the picturesque scenery before you.

From this vantage point near the top of the trail you can see how the paved path wends its’ way through the canyon.

After returning to your automobile and heading south again along the park road, you will finally arrive at areas that contain the stars of the park, namely the petrified wood (interchangably called petrified rock).

These photographs were taken in a section of the park called the Crystal Forest.

As you amble along the paved trail you will come across hundreds of pieces of petrified wood. Although it is called petrified wood, it is not wood at all, but actually stone. It once was wood, as these were formed by the permineralization of toppled trees. In an amazing process, the wood morphs into stone, leaving the rock in a shape that is exactly the same as the host tree that allowed it to form.

In this piece you can even see how the structure of the bark is apparent in the rock.

The photograph above clearly shows the host tree trunk that turned into stone long ago. It almost looks as if someone segmented the trunk with a stone-cutting chain saw.

Again, a clear example of a tree-turned-to-stone.

And another.

When the desert flora and cacti grow in proximity to one another, it creates a magnificent sight, as well as a great photo-op.

These pieces of petrified rock reveal the rings that existed within the tree trunk, and which have been preserved in the permineralization process.

This segment evidences both the rings of the former tree, as well as the bark on the outer surface.

The sections of petrified rock above and below show the coloration that the stone takes on as it morphs. In the gift shops outside the park, one can purchase pieces of petrified wood that have been harvested from private land outside the park. The pieces that are for sale are usually cut smooth and polished, creating a shiny, colorful piece that makes a beautiful display in ones’ home, and becomes a wonderful momento to remind you of your visit to Petrified Forest National Park.

In closing, I would whole-heartedly recommend a visit to the park, preferably with enough free time to hike along at least one of its’ many trails, and to savor the spectacular scenery that only occurs here.