Since registering for a domain name and signing up for a web host (Dreamhost), I have found my self in front of the computer for days on end. Learning about setting up services on the server, FTP programs, HTML code, blogging software, photo gallery software, etc. has been very time consuming.  Switching over from ISDN to satellite broadband, and my continued attempts at networking my computers has also taken it’s share of time. Then, reviewing and uploading photos to the gallery, and writing posts to the blog are time eaters also. All this has come at the expense of ranch projects, so I’m back off to work now!

Yesterday was unseasonably warm here in the Ozarks, so I took the opportunity to drain, clean, and refill the hot tub. Today, I worked on a winter-long project of “parkizing” (def: taking an area of land, and making it look like a park) a stretch of creek that runs for about a mile through our property. This has been a very physical project, involving lots of chain saw and tractor work, but mostly a lot of heavy lifting and hauling.

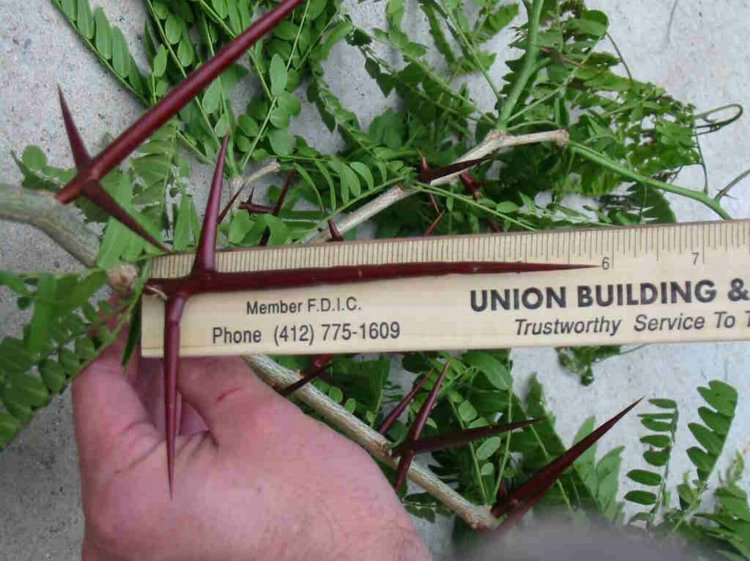

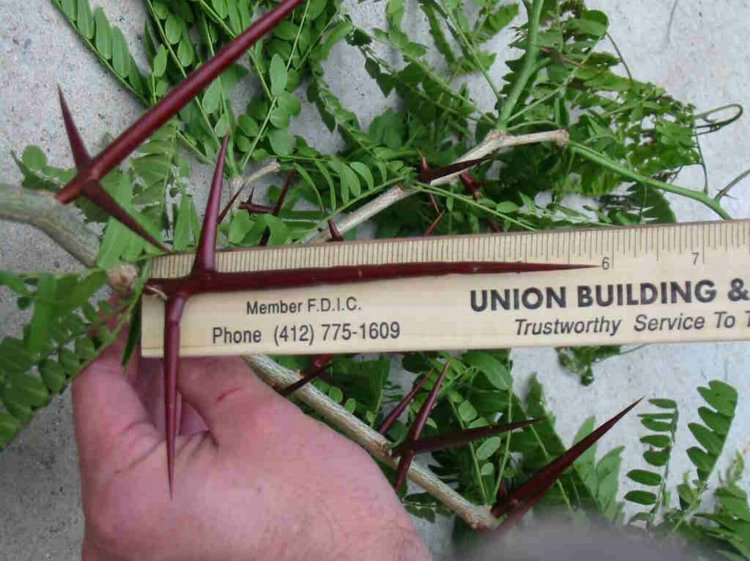

Retta pointed out a low and dangerous limb from a locust tree that was intruding into one of her riding trails, and ask me to remove it. The thorns of these trees are wicked – I can’t count the number of flat tires I have fixed on my tractor as a result of these trees. The only redeeming feature to them is that deer love to eat the seedpods from honey locusts.

Even though the deer like them, there are several located around the horse paddock that I will have to remove. I will probably just cut them up and burn them where they now stand, as handling them is difficult and dangerous.