Ouch!! A sting from a normal sized scorpion can be very painful – I know this from personal experience. But can you imagine encountering a foot-long scorpion? I have come face-to-face with one of these giants, as evidenced by the following photograph.

I ran across this specimen (metallica hadrurus arizonensis) while visiting the Devil’s Rope Museum in McLean, Texas. And if this one isn’t large enough to frighten you, how about a scorpion the size of a human being? It must have existed, because I read about it on the Internet – specifically, here.

But back to the Devil’s Rope Museum, which claims to be the largest barbed wire historic museum in the world, and is the topic of this post.  I visited this museum while passing through McLean, Texas, shortly before writing a  previous post regarding my pathetic little collection of barbed wire and fencing tools.Â

McLean, Texas (pop. 830) lies along the path of old Route 66, which I happened to be exploring this past Fall. After a delightful lunch stop at the Red River Steakhouse (a place with real cowboys and cowgirls seated at the tables, excellent rib eye steaks, and great fresh cobblers included with all meals), the Devil’s Rope Museum caught my eye as I was departing town. Grabbing my camera, I headed inside to see what might be on display.

The museum offers a variety of exhibits related to barbed wire and fencing, as well as barbed wire art, such as the scorpion (as seen in the first photograph), and the woven wire hat, seen here.

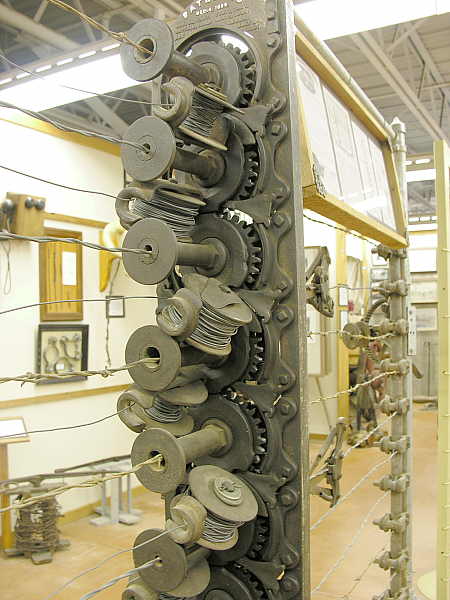

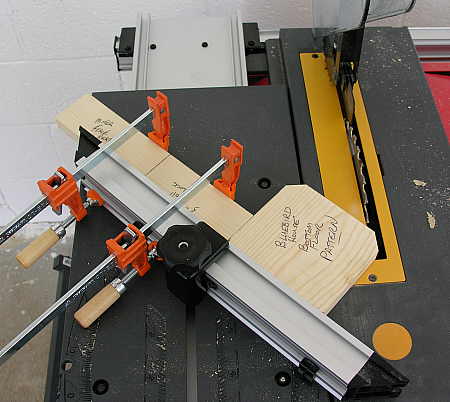

This photograph shows one example of the portable wire fence fabrication machines the museum has on display.

In times past, many rural ranchers utilized the top wire of their barbed wire fencing to transmit electrical communications signals (telegraph, telephone, etc.) from point to point. These ranchers soon became well-versed in the concept of electrical insulators, and began using any appropriate items or materials that might have been on hand at the moment, as seen in the preceding photo.

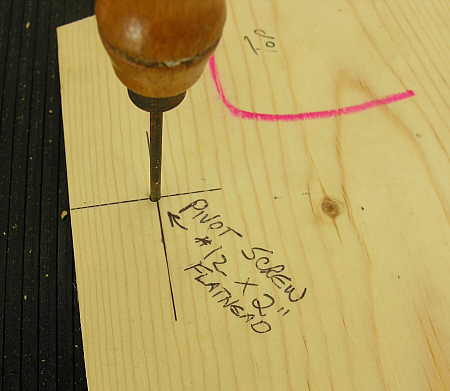

In those parts of the plains states where timber was in short supply, substitute materials would be found for the construction of fence posts. The photo above shows a clever seat/hand drill device used to bore holes in stone fence posts – a daunting task, indeed!

This is an uncommon earth auger designed to be powered by a vehicle’s 12 volt electrical charging system.  Perhaps these tools will make a comeback as a result of $4.00/gallon gasoline.

This is just a small sample of the thousands of styles of barbed wire that the Devil’s Rope Museum has on display throughout the building.

Here are some of the various designs and sizes of fencing staples that are on display, along with an explanation of what the different types of staples are used for.

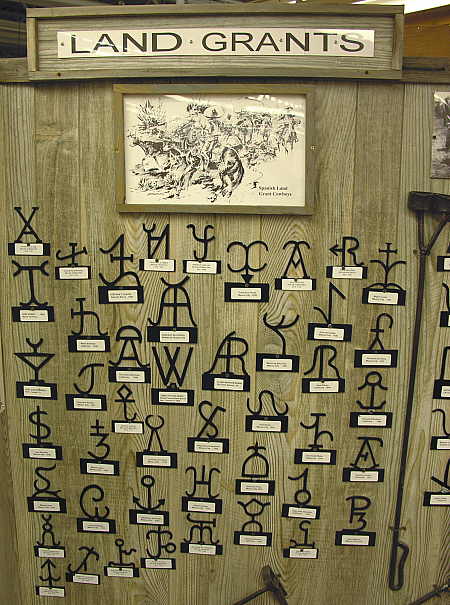

The museum hosts a nice size collection of branding irons and brands, including this example of early land grant brands.

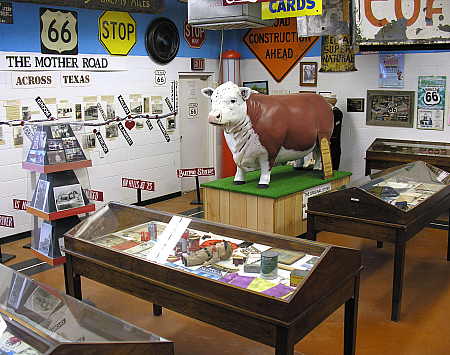

Because the Devil’s Rope Museum is located along old Route 66, the facility includes a small, but nice exhibit pertaining to the Texas portion of Route 66.

On display within this section of the museum is this mock-up of a 1940’s era diner, with all of the appropriate appliances and accouterments.

You may remember reading my previous post about the Big Texan Steak Ranch in Amarillo, Texas. If so, you may be interested to know that the cast model steer on display at the museum (seen above) is the steer that graced the original location of the Big Texan. If you look back at that previous post, you will see that the current steer replica is vastly larger than this original one.

In addition to this small sampling of the exhibits at the Devil’s Rope Museum that I have depicted above, I also viewed a special photographic collection pertaining to the Dust Bowl era that afflicted the mid-west region in the 1930’s. Seeing the disaster that took place, and the human devastation that resulted was a heart breaking experience. Because I did not take photographs of the exhibit (for copyright reasons), I have included  this link to a website containing similar photographs. It is well worth a click over to the site.