Last month I took a road trip from Arkansas to California and back, which is a trip I have taken many times in the past. In order to add a little more interest this time around, I decided to travel over as much of the original Route 66 as was reasonably possible, given the overall time I had alloted for this particular trip. Along the way, I sampled some of delightful places that this route took me near.

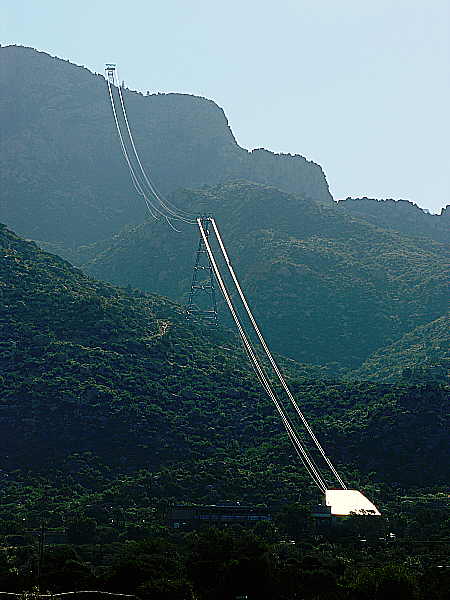

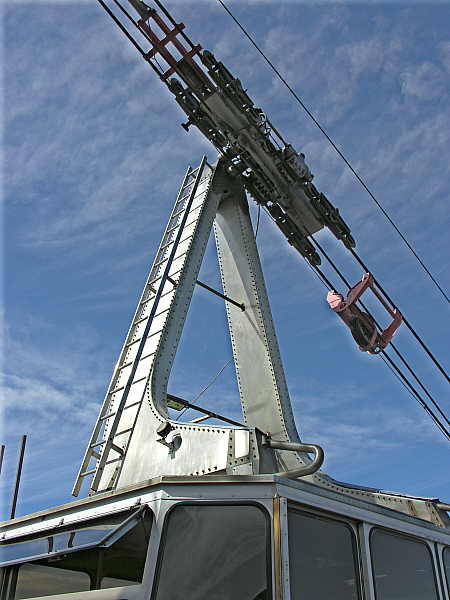

Since my camera is once again off traveling without me, I thought I would share some of the sights that I saw along Route 66 over the next few days. In case you haven’t noticed, I have already posted about several of these sights already. There was the post about the Nation Cowboy and Western Heritage Museum in Oklahoma City, Oklahoma. And then the post about the Sandia Peak Tramway in Albuquerque, New Mexico, and of course the Burma Shave signs  I ran across while driving on Route 66 in western Arizona.

Today’s post is about the Elk City Old Town Museum Complex, located along Route 66 in western Oklahoma. The museum complex was quite impressive, particularly considering the small size of Elk City (population – approximately 11,000).

The complex is comprised of a replica old western town, with all the types of buildings you would expect to see in such a town, along with several museums, some of which I’ll show you in a moment. Above is the Opera House replica (which can be rented for weddings and other occasions).

Here is a bank and mercantile building that is located along one side of the park, which is home to the museum complex.

Inside the buildings are authentic antiques from days of yore, such as the surgical facility shown in the photograph above.

There is a replica train depot which you can visit, along with an authentic railroad caboose that you can walk through.

This is an actual old school house that was originally located in a nearby town. It was dismantled and rebuilt at this sight, and contains the furnishings and accoutrements you might expect to see in an old school house on the prairie.

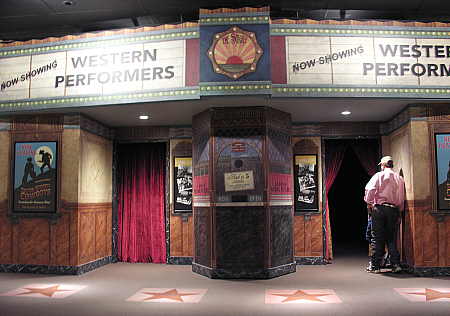

One of the museums contained in the complex is the National Route 66 Museum.  Visiting the Route 66 museum is the reason I sought out the Elk City Museum Complex in the first place.

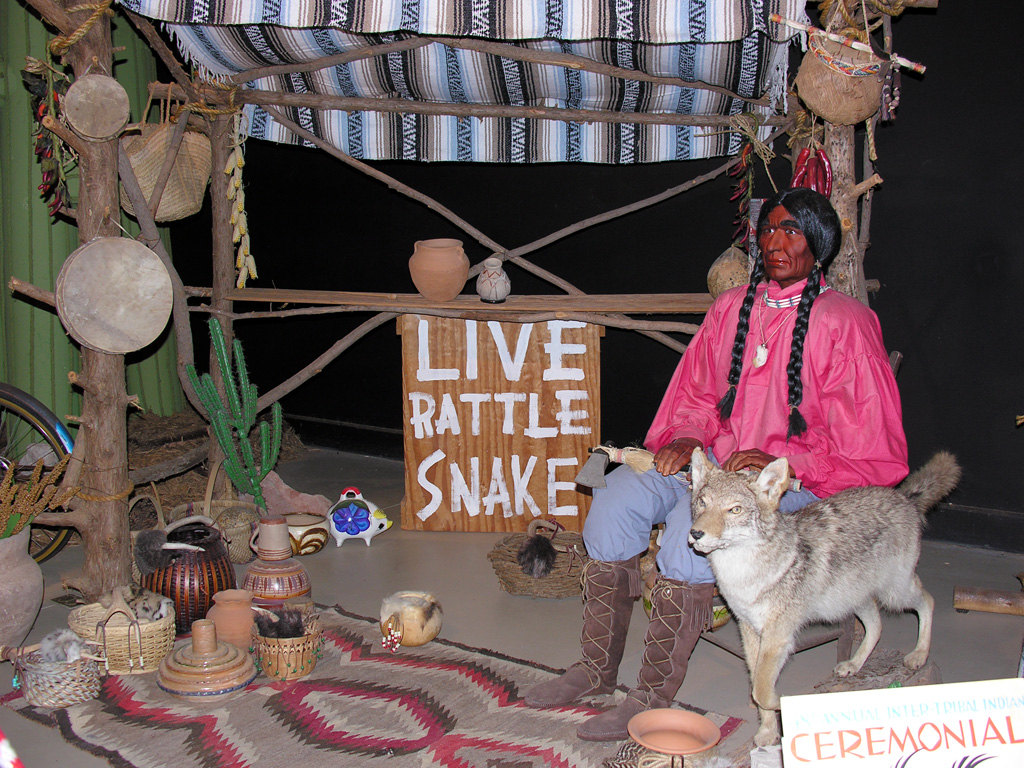

Within this museum are displays of the scenes you would be likely to see while traveling along Route 66, such as the Navajo peddler depicted above, or the old-time service station recreated in the photograph below.

This sailor, hitching a ride along Route 66 in the southeast corner of Kansas, is a very long way from any ocean. I wonder if his destination is the Atlantic, or Pacific ocean?

Considering that the National Route 66 Museum was the reason for my visit, I felt a little let down with it’s contents and displays. I found nothing on display that was particularly unique or compelling, and if it were the only draw to the Elk City Museum Complex, I would have been disappointed.

The portion of the complex that I found most appealing was the Farm and Ranch Museum, which is comprised of an outdoor display area, along with a large indoor facility (seen in the background in the photograph above).

The museum owns a collection of windmills, each one with some special pedigree or unique feature. The style shown above, with it’s unusual blade structure, is designed to operate in, and withstand very high winds.

There are old and varied farm implements on display outside at the Farm and Ranch Museum, many of which have functions that are not immediately recognizable to the average person. All are well signed and documented, however, so that the visitor can learn about these pieces of farm machinery during the course of their visit.

Here is an example of the kind of old farm equipment you will find inside the Farm and Ranch Museum building. The building is quite large and hosts a great number of items – from large tractors and implements, to collections of tiny agricultural U.S. postage stamps, and everything in between.

The Farm and Ranch Museum offers exhibits of items that you may never have seen or heard about, such as the display of hog oilers seen in the photograph above. Hogs would rub up against the oily wheels of the hog oiler, and the coat of oil on the skin of the hogs would help to protect the hogs against flies and ticks.

Here is a very colorful display of old, cast-iron tractor and farm implement seats. There are many more on display at the museum, but these are the only ones that are painted so colorfully.

This wagon is just one of many on display at the Farm and Ranch Museum. In fact, there are several that I saw that would make perfect “yard art” somewhere on our property :)

In conclusion, I would highly recommend a visit to the Elk City Old Town Museum complex. Perhaps not for the National Route 66 Museum, which I found disappointing, but for the excellent re-creation of an old town within the complex, and for the outstanding Farm and Ranch Museum, which (to me) was well worth the time and (modest) cost of admission.