Duane from Geek Acres (see previous post) had a recent post on his site about ticks and the use of guineas in controlling them. Duane and Jennifer have considered owning guineas, and a commentator advised them:

————Â

“DON’T DO IT MAN!!!!!

Guineas may look all tiny and cute and helpful – but they are mean!!!

My parents had some on our farm. They constantly attached our sheep and other birds(including fights to the death). On the other hand they are fairly small. Up to you, just be aware I have talked to several other people who have the same sentiment about them. If any of your dogs are timid and are going to be in the same area as the guineas be aware they might get attacked also.”

————-

We want to take this opportunity to come to the defense of these poor, misunderstood, lovable creatures. If you look closely at the first photo (above), you can clearly see the affection in this bird’s eye – not an iota of meanness is apparent in it’s countenance.

In the photograph below, do the dogs look the least bit disturbed by the presence of the guineas? They’re not, and for good reason. The guineas we’ve known have all been gentle creatures, who display a curiosity towards those around them.

Now, if you are really looking to possess a bird with aggressive tendencies, make sure to get a rooster. They possess wickedly long, strong and sharp spurs, which they are prone to use at the slightest perceived provocation. Imagine placing a carpentry nail against your shin. Now, have a friend(?) whack the nail with a hammer, hard enough to cause the nail to penetrate bone. Ouch!!! That is what the spur of a rooster can, and will, do. Retta has a scar or two to prove it, ask her.Â

The guineas are pretty smart, in their own way. For example, they quickly learn that the discharge chute from my lawnmower emits oodles of lush, green grass. Consequently, when I mow, I have a flock of guineas chasing after me and my mower (I’ll have to ask Retta to photograph this sometime – it is pretty comical, at least it has me grinning as I mow). They have also learned to chase after the tractor as I bush-hog a field. They quickly grab the grasshoppers and locusts that scatter in all directions when I pass. In a fine Pavlovian manner, they come running whenever they hear the sound of the tractor or mower starting. You can almost see them drooling!

We have seen a marked improvement (IE decline) in the tick population in the areas that the guineas patrol. They lead a pretty boring life. Unless nesting, they spend most, if not all, of their waking hours eating ticks (as well as other bugs). They don’t scratch around everything, as chickens do, so your plantings are pretty much safe from them.Â

Guineas play a cute game (at least I think it’s a game) which I call “Guinea Keep-Away”. The guineas usually travel in flocks. When one member of the flock finds a grasshopper, say, he will pick it up in his beak and run away with it. This arouses the suspicion of the rest of the flock, who chase the first guinea to see what it has. The first guinea, invariably, will drop the grasshopper. Another guinea will pick it up and also run with it, until such time as he drops it. Another guinea picks up the grasshopper and runs, and thus the cycle continues. I don’t really know if this is “sport” or not, but it is consistent behavior, and it certainly appears as a game to me. Oh yeah, they also perform this exact behavior with mice (that our cat tortures half-to-death) dangling from their beaks – gross!

Guineas help attract wild turkey to your property. The turkey seem to sense the comfort level that the guineas have around humans and their paraphernalia, and hence are more prone to come around an inhabited site that has guineas.

But lest you think there are no negative traits with guinea fowl, consider this. They are noisy. It is said that they make fine “watchdogs”, in the sense of raising an alarm at anything that arouses their suspicion. The problem is, they suspect almost everything and everyone, so expect to hear a lot from them. And their grating, squawkish rasp sounds much like an axle that hasn’t seen grease in a long, long time (eeek… eeek… eeek… eeek… eeek… eeek… incessantly when aroused). At those times, you can forget about taking that much anticipated nap in the patio lounge! And if you have neighbors that live close by… well, you can imagine.

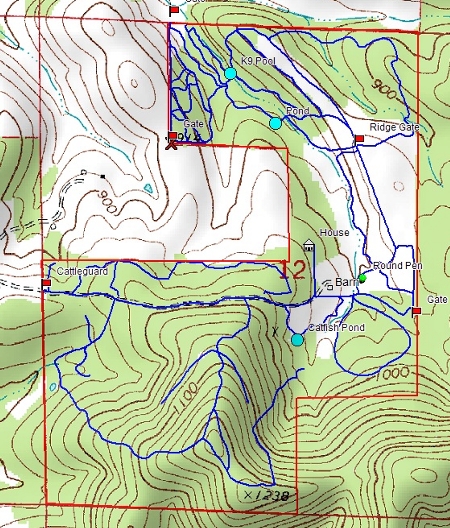

We raise our guineas from keets (chicks), that we usually get shipped from a local hatchery. We have used Cackle Hatchery, in Lebanon, Missouri, and they have been dependable. After raising the keets inside the house for several weeks, we transfer them out to the poultry pen pictured below. It has a concrete footing, an interior portion with roosts, and an exterior “courtyard”.Â

We keep the keets locked up in the coop until they are nearly fully grown. By waiting until they are grown, the guineas seem to develop a sense of home. At that time, we release the birds in the morning to roam around the grounds.  In the evening, the loose guineas return to the pen (sometimes with a little coaxing). As the seasons warm up and summer approaches, some of the guineas decide that they would rather sleep on top of the pen, rather than inside. There isn’t much we can do about it. They are safe from ground predators there, but we believe that we lose several a year to owls swooping down on them at night.

But credit for our success with guineas definitely goes primarily to Retta. It is Retta who buys and raises the keets, and feeds, waters and generally sees to their well-being. And, as the photo below proves, she spends a lot of time in a rigorous training regimen. Here, she is training the guineas to walk in single-file  ;>)

In conclusion, I’ll offer my advice to Duane and Jennifer:Â DO IT MAN!!! You won’t regret your decision.